Handmade bench for testing the alternator and starter

Are you thinking of building an alternator test bench by yourself? Our article will help you realise the idea, we will tell you in detail about the technology of assembling the stand.

An idea to build a test bench for testing alternators.

In order to detect a breakdown of the generator, it may be enough to check the voltage regulator and tension the drive belt. But in most cases, you will have to dismantle the alternator and install it on the stand to diagnose the fault accurately.

Generator diagnostics on a home-made stand

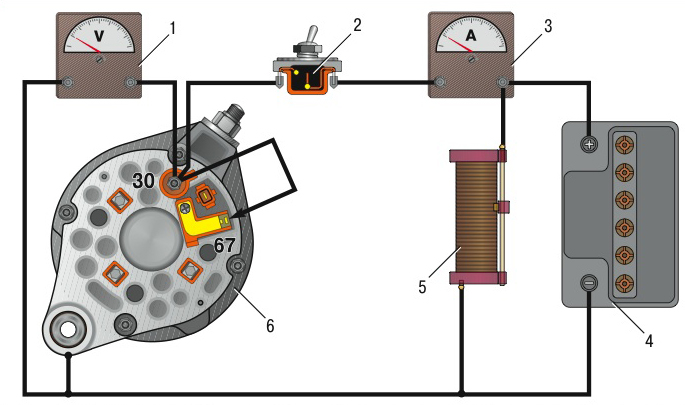

The figure shows the scheme of the stand for repair of alternators, which will not be difficult for most car enthusiasts to assemble.

The illustration shows the order in which the generator should be connected for subsequent testing.

No. 1 voltmeter;

No. 2 switch-off switch;

No. 3 ammeter;

No. 4 battery;

No. 5 rheostat;

No. 6 alternator.

On a homemade stand it is necessary to connect the electric motor, rheostat adjust the voltage strength at the output of the generator to 14V, the rotor speed should be up to 5 thousand revolutions. After running the generator at this pace for two minutes, it is necessary to measure the current output force. When the recoil force is not less than 44 A, the generator can be called working. If the figure is lower, it indicates possible problems with the winding, probably damaged valves (rectifier bridge diodes), wear of brushes.

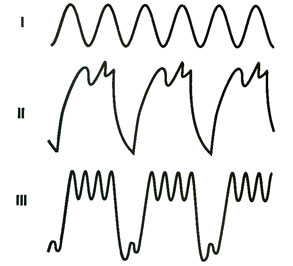

Check the alternator's performance by using an oscilloscope. Rotate the alternator rotor at a frequency of about two thousand revolutions. When there is nothing wrong with the stator winding and the valve, the curve will have the appearance of a saw with equal teeth.

The figure shows an example of three variations of the curve.

1. The generator is running normally;

2. Valve is damaged;

3. Open circuit.

When the alternator is disassembled, you can diagnose the field winding resistance. The normal reading is between 4 and 22 ohms.

Anywhere from 4 to 22 ohms.

It is also possible to test the winding using a signalling device. For testing you will need a battery and a 12v test lamp. The wire that comes from the battery is connected to the rotor, the other wire is connected to the rings. The indicator lamp should not glow during these steps. When it does, it indicates a shorted winding, which means that the rotor must be replaced because it has failed.

Stator winding diagnosis is done when the alternator is disassembled. The stator is tested by connecting a test lamp to each of the winding leads. When the lamp does not glow, this signals that there is a break in the winding. In this case, the stator will need to be replaced or rewound.

Professional equipment for diagnosing starters and alternators

The circuit presented in this article is considered to be the simplest of the possible options. It can be used by students starting their studies. Self-made stands for checking starters and alternators are also found in car services, but the quality of such service is much lower compared to those workshops where professional diagnostic equipment is used.

Customers always pay attention to what tools and equipment the workshop is equipped with. Therefore, a homemade stand is unlikely to attract car owners, rather, they will turn to a service where professional equipment is used. In addition, it is worth remembering that about 90% of cars after 2010, are equipped with generators with digital voltage regulators with the transfer of control signals via LIN-protocol. In this case, it will be extremely difficult to check the alternator operation without an appropriate tester.

Buy professional equipment for diagnostics and repair of starters and alternators is offered by MSG Equipment. The company's catalogue includes stands for large service stations and testers that can be used in small services. Of course, professional equipment has more possibilities than generator and starter stands, which are made artisanally.

Multifunctional and affordable MSG Equipment will increase the efficiency of the car repair shop, help to carry out high-quality and fast diagnostics and repair of starters and alternators.