MS111 – Test bench for diagnostics of vehicle air conditioner compressors

MS111 is intended for health assessment of vehicle climate system compressors operating either on R134a or R1234yf refrigerants, post-maintenance run of compressors, pre-sale testing of new analogs and test report.

Price by request

Online presentationMS111 – Test bench for diagnostics of vehicle air conditioner compressors

Supply voltage, V | 400 |

Supply type | Three-phase |

Drive power, kW | 5.5 |

Dimensions (L x W x H), mm | 900×570×1280 |

Weight, kg | 183 |

Utilizedrefrigerant | R134a, R1234yf |

Refrigerant filtration | Yes (1 µm2) |

Amount of refrigerant in the system, g | R134a – 1100 R1234yf – 1050 |

Test bench filling | Stand-alone filling station |

Type of filling fittings | Automotive HP and LP |

Utilized oil | PAG46yf |

Amount of oil in the system, g | 200 |

Compressor testing | |

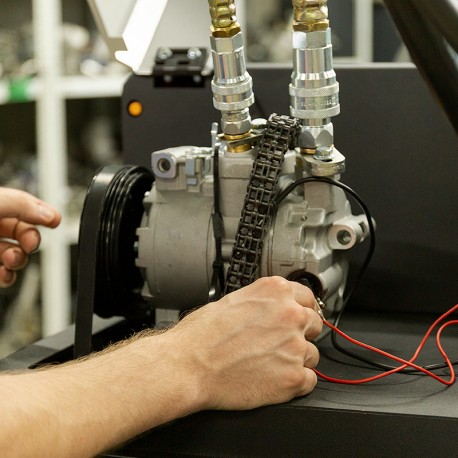

Rated voltage of the diagnosed units, V | 12, 24 |

Drive speed, rpm | From 0 to 3000 |

Drive speed adjustment | Smooth / gradual |

Drive type | Belt V-belt / poly-V belt |

Vacuum line of the unit | Yes |

Refrigerant pumping out of the unit | Yes |

Output parameters | HP, bar; LP, bar; Compr t, °С; Evpr t, °С; PWM %. |

Additional features | |

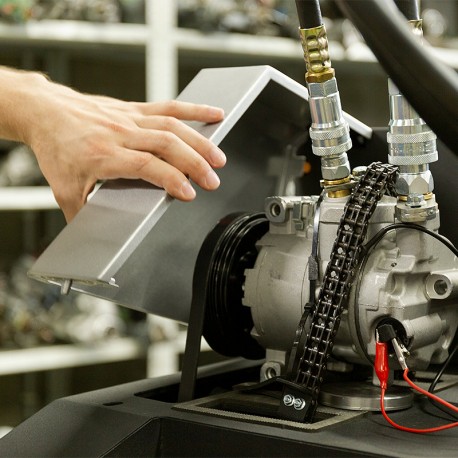

Test results printout | Available |

Firmware update | Available |

Diagnostics results storage | Available |

Connection of external devices | 2 x USB 2.0 |

Internet connection | Ethernet, Wi-Fi (802.11 a/b/g/ac) |

MS111 – Test bench for diagnostics of vehicle air conditioner compressors

Checking the car conditioner

Today, axial-piston compressors with wash plates are one of the most common types of compressors installed in automotive climate systems. Regardless of the compressor type, the condition of oil in the crankcase should be assessed prior to launching the diagnostics of the unit. To obtain an oil sample it is necessary to unscrew the tap screw in the compressor crankcase or simply to drain the oil through high and low-pressure ports.

Transparency of the oil with a slightly green fluorescent liquid is indicative of the good condition of the compressor piston group. On the contrary, if the oil is gray or contaminated with metal shavings, the compressor should be disassembled and repaired. If this is the case, no preliminary diagnostics is required. Before the compressor installation, the system should be flushed directly in the car. Flushing Stand for AC systems MS101P will provide quick and quality cleaning of the AC system pipelines from contaminations.