- Home

- Equipment

- Equipment for diagnostics of starters and alternators

- Equipment for diagnostics of automotive air conditioning system

- Equipment for diagnostics of electric power steering (EPS) unit

- Equipment for diagnostics of power steering unit

- Equipment for diagnostics of brake calipers

- Equipment for diagnostics of shock absorbers

- Equipment for particulate filter flushing

- Equipment for diagnostics of electric vehicles

- Special tools

- Components

- Turnkey business

- Training

- FAQ

- Blog

- News

- Our story

- Location

- Equipment

- Equipment for diagnostics of starters and alternators

- Equipment for diagnostics of automotive air conditioning system

- Equipment for diagnostics of electric power steering (EPS) unit

- Equipment for diagnostics of power steering unit

- Equipment for diagnostics of brake calipers

- Equipment for diagnostics of shock absorbers

- Equipment for particulate filter flushing

- Equipment for diagnostics of electric vehicles

- Special tools

- Components

- Turnkey business

- Training

- FAQ

- Blog

- News

- Our story

- Location

Equipment for diagnostics of power steering unit

- Equipment

- Equipment for diagnostics of starters and alternators

- Equipment for diagnostics of automotive air conditioning system

- Equipment for diagnostics of electric power steering (EPS) unit

- Equipment for diagnostics of power steering unit

- Equipment for diagnostics of brake calipers

- Equipment for diagnostics of shock absorbers

- Equipment for particulate filter flushing

- Equipment for diagnostics of electric vehicles

- Power steering rack shafts

- Popular

- Special tools

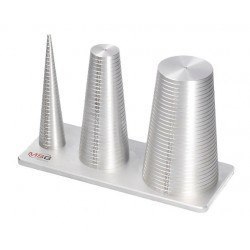

- Power steering pump rotors

- Turnkey business

- Training

- Components

- Electric power steering pump boards

- Equipment spare parts

- Tools for Repair of Power Steering

- Alternators and starters

- Set of tools for repair of starters and alternators for sale in Great Britain

- Set of tools for repair of starters and alternators for sale in Canada

- Set of tools for repair of starters and alternators for sale in the USA

- A set of tools for repairing starters and alternators for sale in Australia

- A set of tools for repairing starters and alternators for sale in South Africa

- Repair kit for starters and alternators for sale in Portugal

- Set of tools for repair of starters and alternators in Spain

- Set of tools for repair of starters and alternators in Brazil

- Steering system

- Tool for repair of power steering system for sale in Canada

- Power steering repair tools for sale in USA

- Power steering repair tool for sale in Great Britain

- Power steering repair tool for sale in South Africa

- Power steering repair tool for sale in Australia

- Tools for power steering for sale in Portugal

- Tools for power steering for sale in Spain

- Tools for power steering repair for sale in Brazil

- Alternators and starters

- Spanish

MS504 – Test bench for diagnostics of power steering pumps

MS504 – Test bench for diagnostics of power steering pumps

Supply voltage, V | 400 |

Supply type | Three phase |

Drive power, kW | 5.5 |

Dimensions (L×W×H), mm | 1100×750×1700 |

Weight, kg | 188 |

Operating fluid | ATF DEXRON II |

Tank volume, L | 22 |

Hydraulic power steering pumps testing | |

Type of tested pumps | single and double-circuit pumps |

Drive speed adjustment, RPM | from 0 to 1500 |

Drive rotation direction | Yes |

Measured fluid flow, l/min | from 0 to 19 |

Measured fluid pressure, Bar | from 0 to 250 |

Measured fluid temperature, °С | from 0 to100 |

Steering rack load simulation | Yes |

MS504 – Test bench for diagnostics of power steering pumps

MS504 – Test bench for diagnostics of power steering pumps

Purpose:

Test Bench MS504 is designed for diagnostics of any mechanically driven single and double-circuit pumps with a pumping capacity of up to 19 l/min. The Test Bench simulates operation of the tested unit in a car. The device reads pressure parameters and measures the fluid flow at different speeds. It can detect such faults as leaking, roaring, relief valve sticking, and bodywear.

Test Bench MS504

- tests all the types of hydraulic power steering pumps;

- is equipped with a pump shaft speed governor: from 0 to 1500 RPMs;

- is equipped with a measuring device that reads all the parameters necessary for detection of the HPS pump operation failure.

The manufacturer: MSG Equipment

Supply voltage, V | 400 |

Supply type | Three phase |

Drive power, kW | 5.5 |

Dimensions (L×W×H), mm | 1100×750×1700 |

Weight, kg | 188 |

Operating fluid | ATF DEXRON II |

Tank volume, L | 22 |

Hydraulic power steering pumps testing | |

Type of tested pumps | single and double-circuit pumps |

Drive speed adjustment, RPM | from 0 to 1500 |

Drive rotation direction | Yes |

Measured fluid flow, l/min | from 0 to 19 |

Measured fluid pressure, Bar | from 0 to 250 |

Measured fluid temperature, °С | from 0 to100 |

Steering rack load simulation | Yes |