When the car owner faces a breakdown of the alternator, the first thing to think about is its repair, not replacement for a new one. That’s because it’s cheaper to repair an alternator than to buy a new one. In addition, it is not difficult to find a place where you can repair the alternator, as the service is very common at the service station.

What breaks down in the alternator and what parts can be replaced?

All modern alternators, like their ancestors, are designed quite simply, so the list of faults is not large:

• wear or destruction of bearings;

• failure of diode bridge;

• failure of the voltage regulator;

• ultimate wear of brushes;

• closing and/or breaking of the stator winding;

• closing and/or breaking the winding of the rotor;

• wear collector rings.

The simplest and cheapest repair is replacing brushes, diode bridges, and voltage regulators. The next most difficult repair is its replacement bearings, because, it is necessary to completely disassemble the alternator. Repair of faults associated with the rotor and stator is considered the most time-consuming, and therefore the most expensive.

Car alternator diagnostics

In order to identify a defective assembly in the alternator it is necessary to diagnose it on a special test bench. Only on the test bench, it is possible to recreate all working conditions similar to what the alternator experiences on the car and at the same time to eliminate the influence on the measurement results of the electrical system elements of the car. Alternator diagnostics on a special test bench allow us to accurately determine the condition of all electrical components of the alternator. Mechanical faults are determined by visual inspection of the dismantled alternator assemblies.

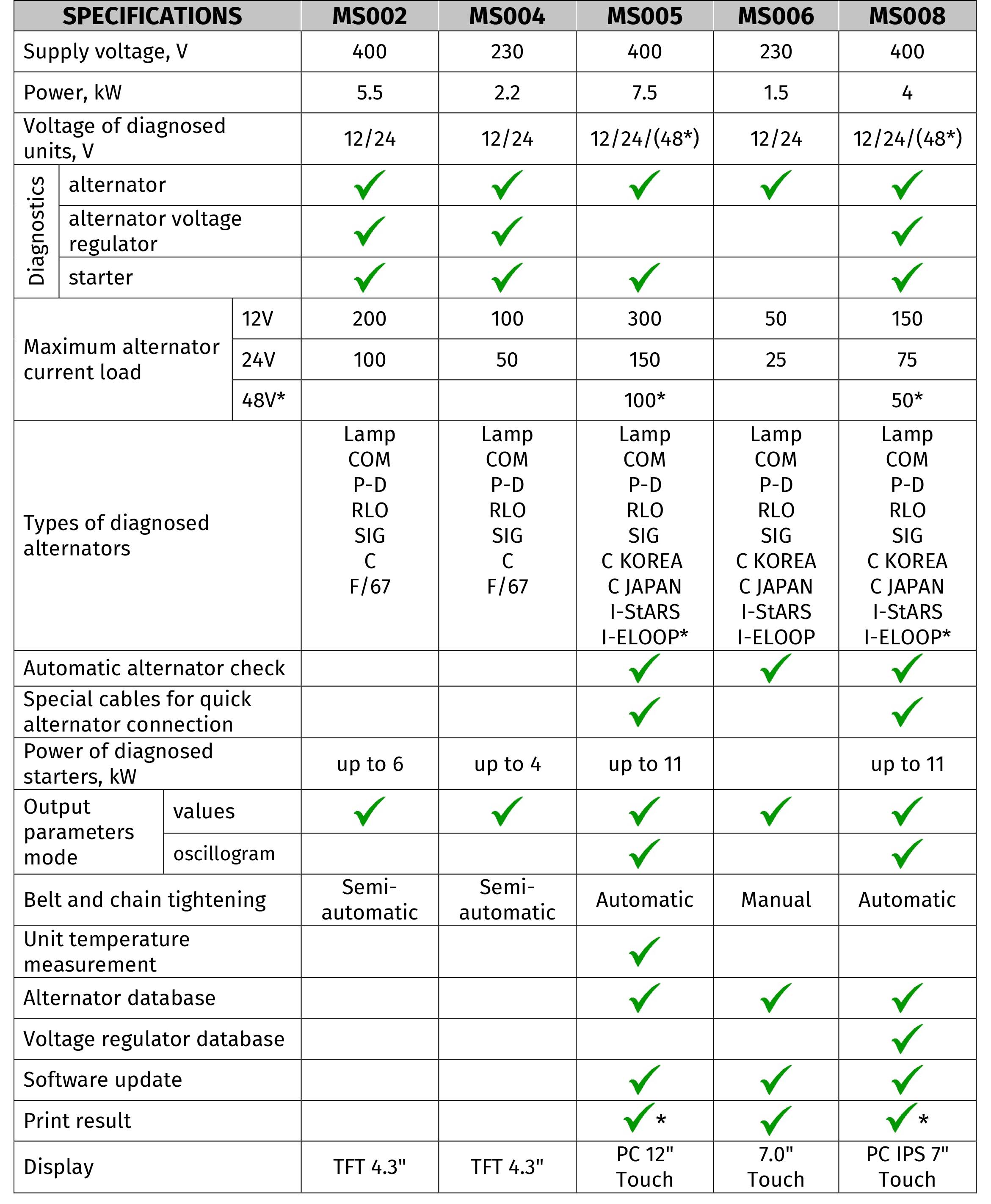

For those who are faced with the question of selecting equipment for the diagnosis of alternators - TM MSG Equipment offers a whole line of test benches. They are all different in power, size, and functionality. The simple and affordable MS006 test bench can be successfully used at any service station to determine the good condition or fault of the car alternator. The more powerful MS002 COM and MS004 COM test benches are capable of diagnosing 24V light and medium-load trucks. MS005 and MS008 are the most advanced alternator diagnostic test benches on the market.

Features of test benches MS005 and MS008:

• displaying of output voltage and alternator current as the oscillogram;

• starter diagnostics results are displayed as a diagram of the changes of the current and the terminal K30, K50, K45 voltage;

• manual automatic diagnostics of alternators;

• recording and printing of the diagnostics results;

• alternator database;

• database of voltage regulators separate from the alternator (MS008 only);

• convenient mounting of a unit, automatic tension of alternator drive belt;

• special diagnostic cables for quick connection to alternators (optional);

• thermal imaging camera for control of the diagnosed unit temperature or locally heated spots (MS005 only);

• touch-screen;

• costless automatic update of the software.

Everyone will be able to choose for themselves the best option. In order to make the choice easier we have prepared a comparative table of all our test benches for the diagnosis of alternators.

If you want to know more about diagnostic test benches for alternators - consult our managers. Write to the messenger or call: +38 063 745 19 68 (Viber, WhatsApp, Telegram).

COMMENTS