In recent years, there has been a significant leap in the global automotive industry towards electric vehicles (EVs). These vehicles are powered by lithium-ion batteries, which are the key component of an electric car. But did you know that there are many different types of lithium-ion batteries used in electric vehicles today?

Currently, the industry has developed six types of lithium-ion batteries, primarily distinguished by the chemical composition of the positive electrode (cathode). The names of these lithium-ion batteries are derived from the elements used in the cathode:

LCO | Lithium Cobalt Oxide (LiCoO2)

LMO | Lithium Manganese Oxide (LiMn2O4 and Li2MnO3)

NMC | Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2)

NCA | Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2)

LFP | Lithium Iron Phosphate (LiFePO4)

LTO | Lithium Titanium Oxide (Li4Ti5O12)

Naturally, there are many more chemical compositions of lithium-ion batteries than those listed above, but not all of them are industrially produced.

In the automotive industry, three types have found application: LFP, NMC, and NCA. Although LMO batteries were used in electric vehicles during the early stages of Li-ion battery adoption, they have now been replaced by more advanced types. It's worth noting that automakers are not strictly tied to a specific type of battery; even within a single model, different types of batteries may be used.

Comparison of NMC, NCA, and LFP Batteries

Each type of battery has its unique properties, both positive and negative.

Energy density refers to the amount of energy (Wh) a battery can store per unit weight or unit volume. Modern technologies have achieved an energy density of around 230-250 Wh/kg for NMC batteries, approximately 322 Wh/kg for NCA batteries, and LFP batteries generally have an energy density ranging from 130-160 Wh/kg. However, in practice, the difference in the range of an electric vehicle between NMC and LFP batteries is minimal because NMC batteries are recommended to be charged up to 80% to preserve their lifespan, while LFP batteries can be charged up to 100% without significant degradation.

Safety is of utmost importance, especially following several cases of Tesla car fires. LFP batteries lead in safety due to their excellent thermal and chemical stability, as well as their ability to deliver significant power without overheating, minimizing the risk of overheating or combustion, unlike NCA/NMC batteries.

Temperature stability varies between battery types. LFP batteries perform better at high temperatures, while NCA/NMC batteries excel at low temperatures. For example, at -20°C, an NMC battery may retain around 70.14% of its capacity, while an LFP battery may retain only 54.94%. Therefore, NMC batteries are a better choice for applications in low-temperature environments.

Service life is where LFP batteries outperform NMC/NCA batteries. LFP batteries can withstand up to 3000 cycles at a charge/discharge rate of 1C and 100% depth of discharge. If the depth of discharge is kept above 80%, LFP batteries can endure up to 4500 cycles. In the same conditions, NMC batteries typically achieve an average of 1000 to 2000 cycles, while NCA batteries have a shorter lifespan of 500 to 1000 cycles.

Environmental friendliness is a key motivation for the development of electric vehicles. LFP batteries surpass NMC and NCA batteries in terms of ecological safety. Cobalt, which is used in NMC and NCA batteries, is a toxic substance that has negative effects on living organisms.

Price-wise, there is almost parity among the different battery types. The raw materials for NMC and NCA batteries are more expensive than those for LFP batteries. However, the production process for LFP batteries is more complex, making them costlier. As a result, the price difference between these two battery types (with the same capacity) is approximately 5-15% in favor of LFP batteries.

This comparison provides a general overview of the advantages and disadvantages of NMC, NCA, and LFP batteries. LFP batteries are significantly safer to operate and have a smaller environmental impact, which is why they are becoming the predominant battery type for electric vehicles. In China, the largest producer of lithium-ion batteries, LFP batteries currently account for over 60% of the total production volume.

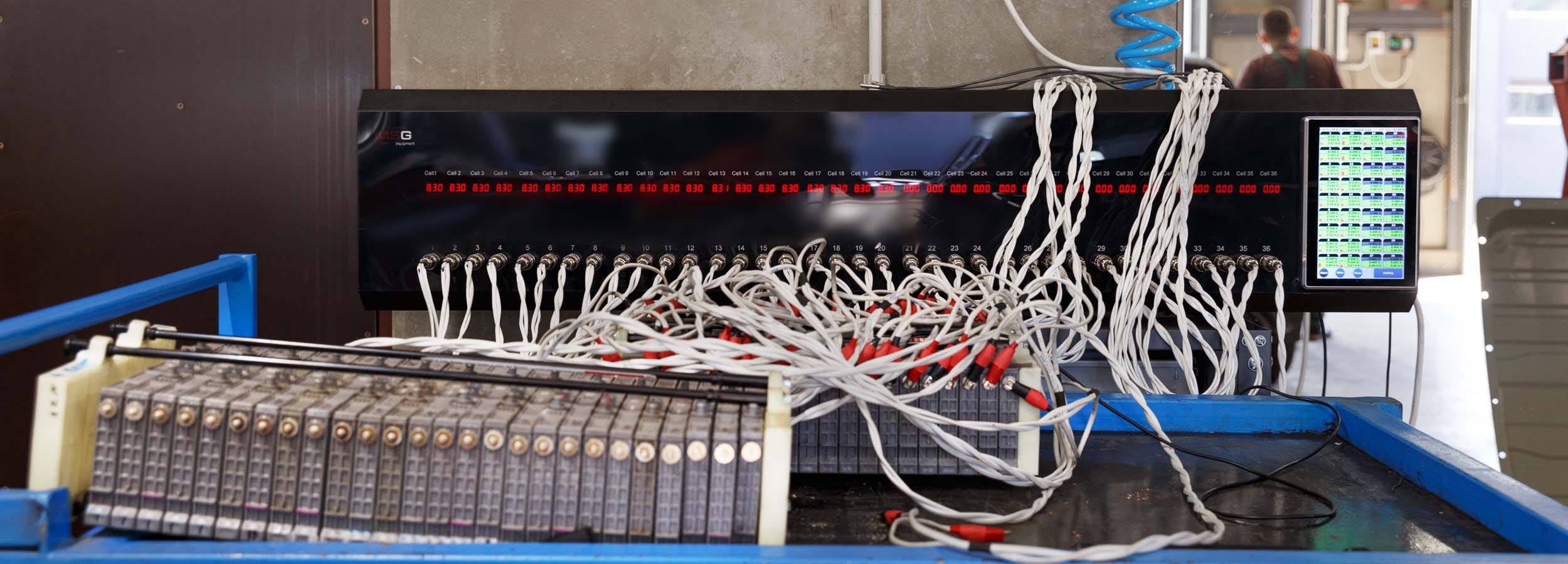

Despite the differences in the chemical composition of lithium-ion batteries, the MS800 tester can detect faulty battery modules in hybrid and electric vehicles. The tester allows for the simultaneous diagnosis of 36 lithium-ion battery modules. The diagnostic process for electric vehicle battery modules is performed automatically.

The capabilities of the MS800 tester include:

- Diagnosing high-voltage battery modules by determining their capacity.

- Balancing the voltage of series-connected battery cells that have become imbalanced over time.

- Preparing the battery for installation in a vehicle by balancing the voltage of all modules.

- Preparing the modules for storage by charging them to a specific level.

If you want to learn more about the MS800 tester, please contact us via messenger or call +38 063 745 19 68 (Viber, WhatsApp, Telegram)

COMMENTS