Electric vehicles are gradually filling our roads. In just a few years, they have gone from being a novelty to a mass form of transportation. One of the advantages of owning an electric vehicle is the absence of the need for regular maintenance. However, the operation of electric vehicles poses new challenges for their owners. It is well known that any battery loses its capacity over time. Therefore, the remaining autonomy and battery life are the main concerns for electric vehicle owners. Since the traction battery is the most expensive component, let's discuss how to determine its condition.

Criteria for evaluating an electric vehicle battery

There are two commonly accepted criteria for evaluating the condition of any battery:

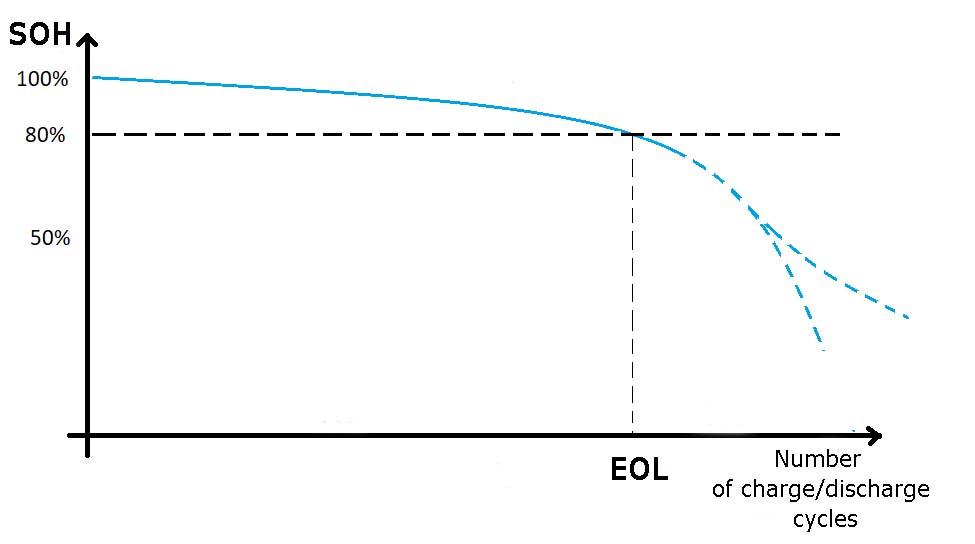

1. SOH (State Of Health) – the remaining capacity of the battery, expressed as a percentage of its nominal capacity.

2. EOL (End Of Life) – this criterion indicates the end of the battery's lifecycle, calculated based on the number of charge/discharge cycles it has undergone.

The first criterion is the primary one because it provides an understanding of the current battery condition. A decrease in SOH leads to a reduced driving range after charging.

The second criterion, EOL, informs us that after a certain number of charge/discharge cycles, the battery may rapidly lose its capacity. Evaluating this parameter is challenging in practice due to the erratic nature of battery charge/discharge cycles.

Methods for independently determining the battery status of an electric vehicle:

- Range estimation;

- Charging efficiency;

- Diagnostic tools provided by the vehicle itself.

The first method for evaluating the battery status of an electric vehicle is monitoring the vehicle's driving range. Range estimation takes into account factors such as driving style, terrain, and weather conditions. If you notice a significant decrease in the current range compared to the specified value, it is a clear sign of deteriorating battery condition.

Pay attention to the amount of electricity required for a full charge of the electric vehicle's battery. An increase in charging costs can also be an indicator of deteriorating battery condition.

Many electric vehicles are equipped with diagnostic tools or software that provide information about the battery's condition, such as the Leaf Spy app for the Nissan Leaf. These tools can provide insights into battery voltage, temperature, cell balancing, and other important parameters. Studying the vehicle's user manual will help you understand what diagnostic functions are available and how to interpret the data obtained to evaluate the battery's condition.

Determining the battery status of an electric vehicle using professional diagnostic tools

At service stations, special diagnostic scanners are used to read information from the battery management system (BMS) of an electric vehicle. For example, the Consult 3+ is used for working with the entire range of Nissan electric vehicles and hybrids, the LOKI exclusively works with Tesla electric vehicles, and the Xentry Diagnostic is a dealer diagnostic device for Mercedes electric vehicles and hybrids. These tools allow service technicians to read data that helps assess the battery's condition.

In recent years, technologies for diagnosing and predicting battery conditions using artificial intelligence have been developed. The essence of this battery condition checking method is as follows:

- A special device is connected to the vehicle's OBD port.

- Then a static test is conducted, during which necessary diagnostic data is collected.

- Next, a dynamic test is performed, gathering data during brief accelerations of the vehicle.

- In the final stage, artificial intelligence is used to analyze the collected information and draw conclusions about the current battery condition.

Determining the battery status of an electric vehicle in the event of a failure

The battery of an electric vehicle can fail, similar to how the internal combustion engine of a conventional car can. In such cases, the MS800 tester is used to determine the battery's condition. This tester measures the capacity of each battery module and, based on the results and the expertise of a trained specialist, draws conclusions about the overall battery condition. Testing the electric vehicle battery with the MS800 tester helps identify which cells have lost capacity, providing insight into how to repair them and estimating the cost.

Conclusion

Methods for evaluating the battery status of electric vehicles are constantly evolving. It is now widely understood that the Battery Management System (BMS) plays a crucial role in assessing the condition of traction batteries during operation. Regular periodic checks of the battery's condition can increase its lifespan and enhance the safety of electric vehicles. In the event of a battery malfunction, testers such as the MS800 are already available to perform battery diagnostics.

COMMENTS