The MS900 stand is equipment designed for cleaning diesel particulate filters (DPF). Using DPFs helps minimize the amount of harmful substances released into the environment along with exhaust gases. Regular DPF cleaning enhances the eco-friendliness of vehicle operation.

Features and Advantages of the Equipment

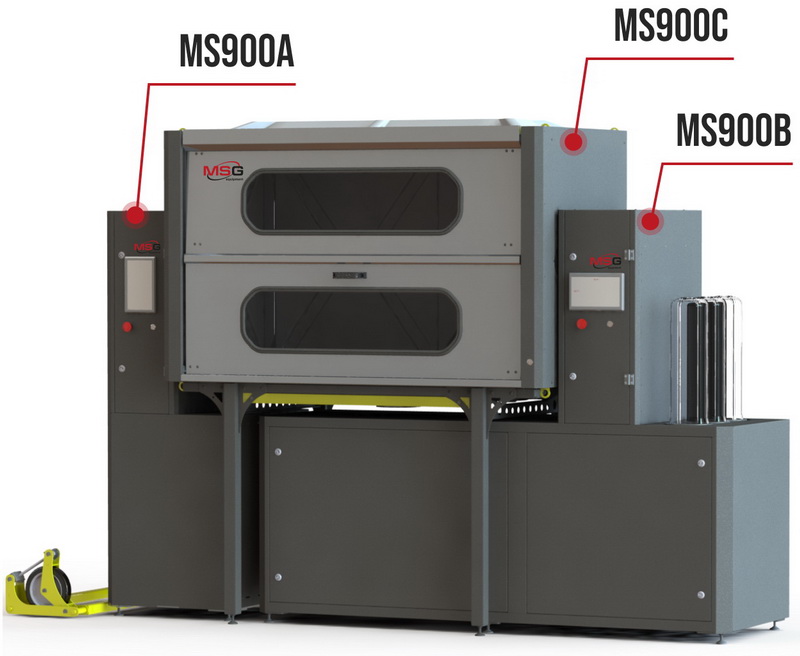

The DPF cleaning machine MS900 features a modular design, consisting of separate self-contained modules A, B, and C, each serving a specific purpose: diagnosis, cleaning, and drying of DPFs, respectively. The structural features of the system offer the following advantages:

- Ease of installation: Separate modules are easier to transport and assemble on-site.

- Compactness: The stand doesn't occupy much space in an auto service center.

- Universality: The cleaning chamber's capacity is sufficient to accommodate filters from various models of both light and heavy vehicles.

- Convenience: DPF cleaning is performed automatically.

- Productivity: Equipping the stand with two MS900C modules allows servicing two filters simultaneously, doubling the number of visitors served by the auto service center.

- Flexibility: The software allows customization of the equipment's operation to match specific filter models.

The built-in memory enables the DPF cleaning machine to store frequently used working parameters. This means that users don't need to input the settings again when reusing the equipment. Additionally, relevant data can be quickly printed using a printer.

Working Process of DPF Cleaning

The DPF filter washer machine MS900 cleans filters without using any cleaning agents. The process takes 30-60 minutes (depending on the type of equipment being cleaned) and includes the following steps:

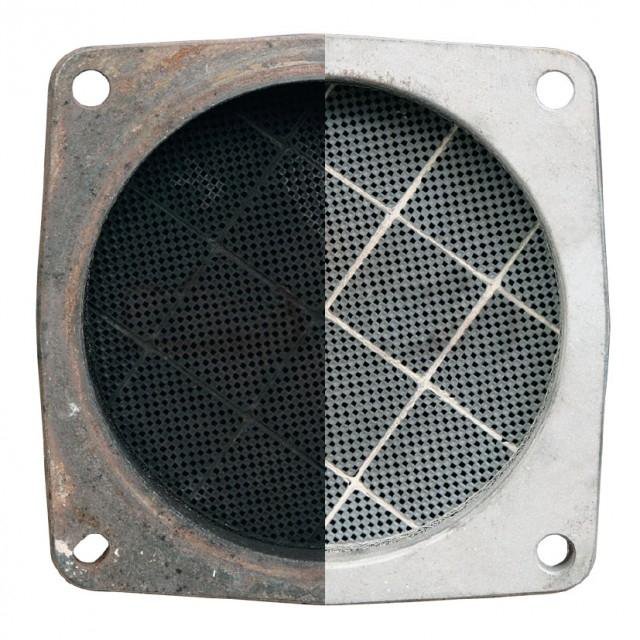

- Checking the ceramic filter's integrity before cleaning.

- Installing and securing filters in special fittings.

- Connecting the DPF to the diagnostic module MS900A.

- Programming the necessary parameters on the touch screen control panel and starting the process.

- Connecting to module MS900B and initiating the cleaning process.

- Drying the cleaned filter by connecting it to module MS900A, where the procedure is carried out with hot air at temperatures up to 80 degrees.

- Rechecking the cleanliness of the filter to ensure the operation's success and comparing the readings before and after cleaning.

The duration of the cleaning depends on the filter's size and its degree of contamination, which is automatically determined by the system. Only filtered water is used for cleaning. The manufacturer of diesel particulate filter cleaning equipment provides two years of warranty service. Auto service center specialists will find it easy to understand and operate such a system.

COMMENTS