Humanity increasingly understands the importance of caring for the environment, so environmental requirements are becoming stricter. Since the Euro-4 standards came into force in 2005, all diesel vehicles must be equipped with soot filters. However, what benefits the environment doesn't always make life easier for ordinary people. The soot filter has become an integral part of the car, and it's essential to know how to address problems with it.

What is a soot filter and what problems can occur?

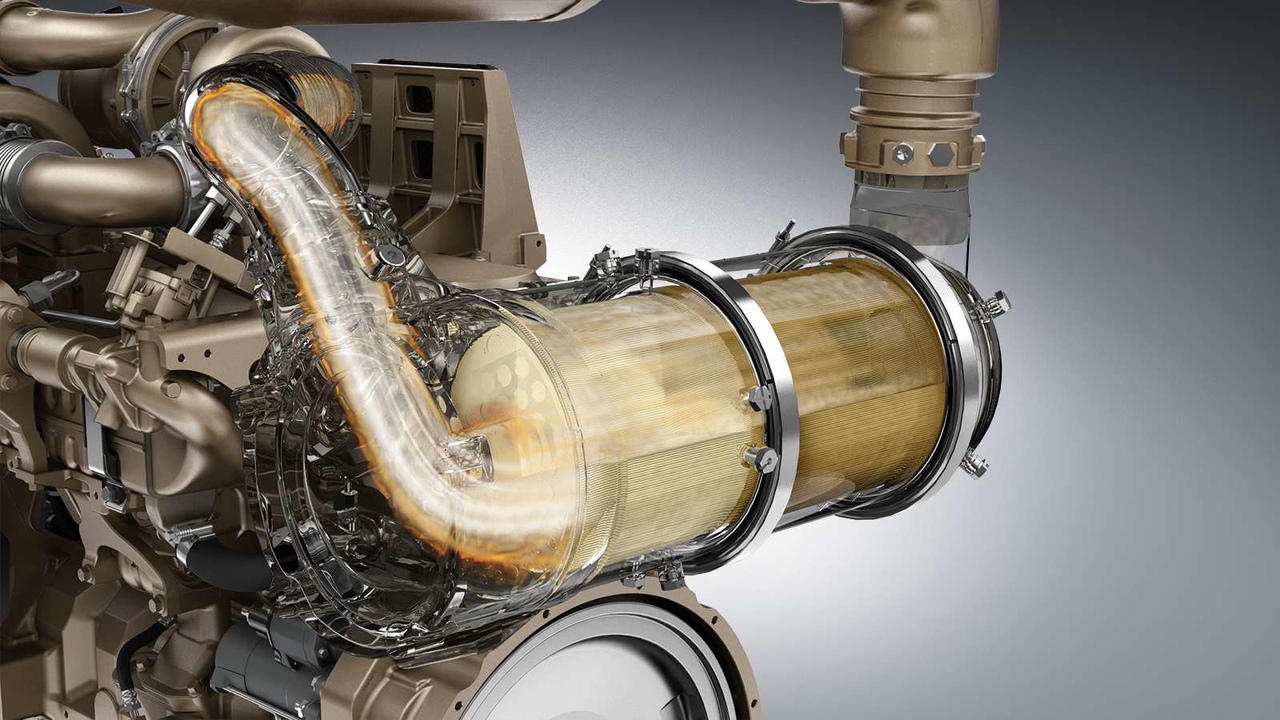

The main danger that diesel cars pose to the environment and people is the large amount of soot contained in exhaust gases. Soot consists of fine graphite particles combined with unburned carbon particles. Inhaling it is as harmful as inhaling coal dust. The filter's task is to capture this soot. However, due to the high amount of soot produced during diesel engine operation, the filter quickly fills up. Therefore, each diesel particulate filter (DPF) includes a self-cleaning or regeneration function. The self-cleaning of the soot filter is activated by the vehicle's electronic control unit (ECU) and occurs unnoticed by the driver.

There are two types of regeneration depending on the construction:

1) Heating exhaust gases to 600-800°C. Used in vehicles where the filter is installed near the engine. This system is often called DPF, although this is not entirely accurate.

2) Burning at lower temperatures using a cerium-containing additive. This system is mainly used in French cars where the filter is placed in the middle of the exhaust system, often called FAP (filtre à particules).

Both options have drawbacks as minor engine malfunctions can block the regeneration process. Self-cleaning of the soot filter may also not start if the vehicle constantly moves in heavy city traffic. A clogged filter leads to increased fuel consumption, reduced engine power, and starting issues.

As new original parts are very expensive, and substitutes either do not exist or lack the necessary quality, car owners are forced to solve the problem by either removing or cleaning the filter. The first option is daunting due to the need to reprogram the vehicle's ECU to lower emission standards, potentially causing issues with regulatory authorities. The second option involves uncertainty about the procedure's effectiveness and safety.

Methods and equipment for cleaning DPF

All methods of soot filter cleaning have their pros and cons. For example, the ultrasonic method, despite its undeniable effectiveness, is expensive and almost unsuitable for cleaning soot filters of trucks. Thermal and pneumatic methods can only be considered as stages in a complex procedure.

The chemical method, often referred to as "soot filter washing," appears effective compared to others but also has drawbacks due to its technology and materials used. The chemical cleaning method involves filling the DPF with a potent chemical. This doesn't always require dismantling the filter – the filter cells can be soaked with the liquid even through the sensor hole. The main disadvantages of chemical cleaning are:

- The glaring non-ecological nature of the method. The used liquid is unsafe for both the environment and the health of the personnel performing the work.

- The amount of time required. The filter "soaking" duration is 8-10 hours.

While chemicals yield results, measuring the filter's condition after such cleaning is impossible, unlike professional stands.

MS900 stand and its main advantages

Our developed MS900 soot filter cleaning stand operates on an entirely different principle. No chemicals are used, except in cases where the DPF needs preliminary cleaning from engine oil. The cleaning method in our stand is a combined hydro-pneumatic one. Warm water circulates in a closed loop, and compressed air pulses are used.

Advantages of this soot filter cleaning equipment include:

- Low cleaning cost, consisting only of electricity and personnel wages.

- Fast cleaning process, with a complete diagnostic and DPF cleaning cycle taking no more than 2-3 hours.

- Versatility, allowing the cleaning of filters from any vehicle and functioning as catalyst cleaning equipment.

- High productivity, with the MS900’s modular design enabling simultaneous washing and drying of filters.

- Convenience and functionality, with processes being highly automated and results being savable or printable.

COMMENTS