The alternator is a crucial component of a vehicle's electrical system, responsible for powering all electrical components. A malfunctioning alternator can lead to both discomfort while driving and complete immobilization of the vehicle. Understanding the main signs of alternator failure and diagnostic methods can help detect the problem in time and prevent further complications.

Common Signs of Alternator Failure

The most common signs of a faulty alternator manifest as changes in the operation of the vehicle's electrical system. Here are some typical symptoms:

Battery discharge: If the car won't start after being parked overnight, despite having a relatively new battery, the alternator may not be able to maintain the battery's charge at an adequate level.

Dim headlights: When the alternator can't handle the load, the headlights may appear dimmer than usual. This is especially noticeable at idle speed, as the alternator produces less electricity in this mode.

Electronics malfunctions: A malfunctioning alternator may cause various systems to malfunction, such as multimedia systems, the instrument panel, air conditioning, power windows, and others.

Noises under the hood: Whistling or buzzing sounds may indicate a faulty alternator belt or bearings. These noises usually become louder as the engine speed increases.

Engine RPM instability: If the alternator is unable to provide the required amount of energy, this can lead to ignition system malfunctions, particularly at low RPMs.

How to Confirm the Problem is the Alternator?

First, using computer diagnostics, check for any error codes (DTC) that indicate alternator failure. For example, codes such as P0560, P0562, P0563, P0620, and similar ones may appear.

Next, special equipment such as the MS015A or MS016A testers should be used. These testers allow you to control the alternator independently of the engine control unit. This helps determine whether the fault lies in the alternator or in the alternator control circuit. This is straightforward: if the symptoms persist when controlling the alternator with the tester, the issue is within the alternator itself. Otherwise, the fault should be traced to the wiring, cable connections (connectors), or the engine control unit. Thus, the MS015A and MS016A testers help localize the source of the problem without removing components from the car and can also test the functionality of the alternator’s voltage regulator, which is a common cause of failure.

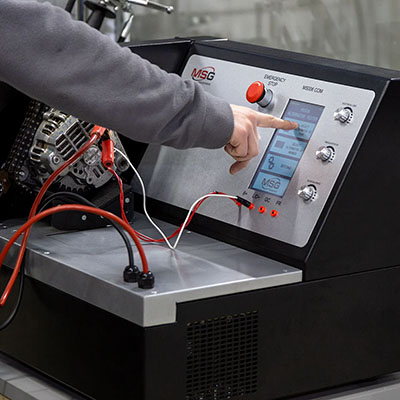

Another method to diagnose alternator failure is using a special test bench such as the MS005, MS005A, MS002A, or MS006. For this, the alternator must be removed from the vehicle. Testing the alternator on a bench not only confirms if it’s faulty but also identifies the cause of the malfunction:

• Voltage regulator failure,

• Coil damage,

• Defects in the diode bridge.

This opens up the possibility for alternator repair, providing additional revenue and greater customer loyalty since they will be able to spend less money and time on car repairs.

Conclusion

The alternator is the heart of a vehicle's electrical system. Its failure can manifest in various ways, from rapid battery discharge to flickering headlights. Having the appropriate diagnostic equipment at a service station allows for quick and accurate assessment of the alternator's technical condition and effective resolution of any issues.

COMMENTS