MS004/MS002 test benches used for diagnostics of automotive alternators, voltage regulators and starters have a high potential of testing a large number of units with different parameters.

(TEST BENCHES FOR STARTERS AND ALTERNATORS)

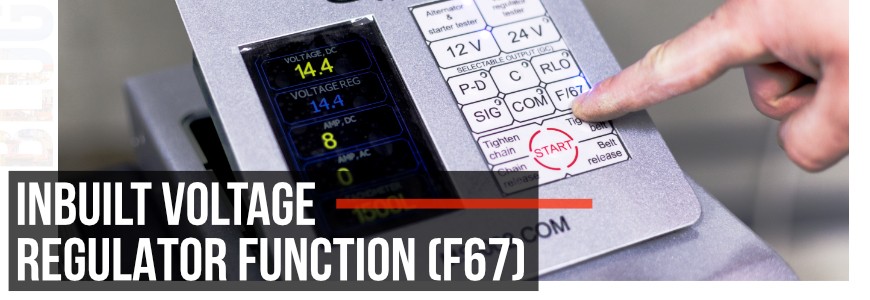

(TEST BENCHES FOR STARTERS AND ALTERNATORS) Let’s take a closer look at one of the multiple useful functions (capabilities) of these test benches – F67 (the name comes from the identification code of the brush connection terminal). F67 is essentially a voltage regulator mounted into the test bench (MS004 MS002) that maintains the alternator output voltage set by the bench operator to test 12V alternators without voltage regulators.

A voltage regulator is one of the most vulnerable components of the alternator. When the alternator is found faulty, the testing usually is being interrupted as the fault is considered to be detected. The testing procedure is restarted only after the replacement of the voltage regulator, which is a mistake as the possible cause of the breakdown is to be located first. It can be:

- electrical fault including excitation winding turn-to-turn fault;

- rectifier fault (diode breakdown).

If these faults are detected in the tested alternator, the chance to damage the newly installed voltage regulator is quite high, especially when the alternator is diagnosed under high load.

That is why if the alternator voltage regulator is considered to be faulty, all the other components of the alternator should be tested first using the function of the inbuilt voltage regulator (F67).

If no other faults have been detected, the new voltage regulator can be safely installed and the diagnostics of the unit in assembly with the new voltage regulator can be performed once again to make sure the alternator is healthy now.

The use of MS004/MS002 test benches for automotive alternators, starters, and voltage regulators enables quality diagnostics of these units without applying any additional measuring devices.

COMMENTS