Diode bridge

The direct current alternators have been installed into cars long ago. Currently, the manufacturers produce the vehicles equipped with the alternating current alternators because these alternators have the less weight and dimensions while their capacity is the same.

What are the functions of diode bridge and how it operates?

The automotive alternator generates three-phase alternating current. At the same time, all the automotive consumers require the direct current voltage. For its generation, the alternator design includes a diode bridge. The diode bridge operation principles base on the feature of the diode bridges to conduct the electric current only in a single direction.

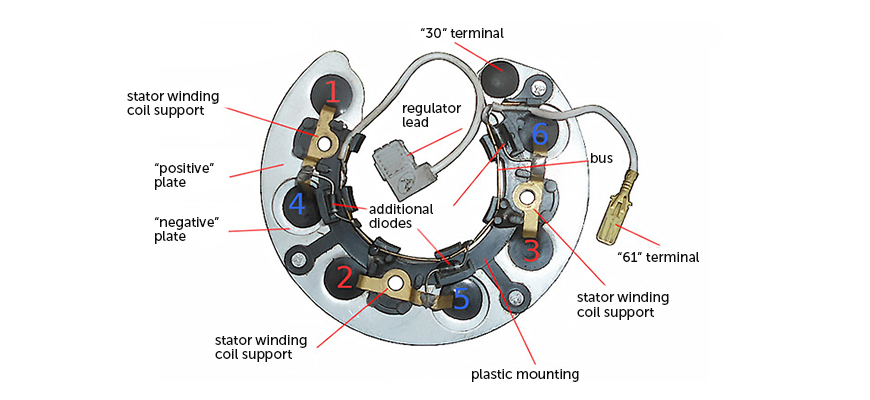

The name of a component indicates its design. The diode bridge consists of the diode group connected bridge circuit. The diode bridge contains two aluminum heat sinking plates that are connected by the anti-short bushings. One plate of the diode bridge is connected to the alternator body, the second - to the output that transfer the direct current to the consumers. There are three or four diodes on every plate, depending on the alternator design. The diode bridge with six diodes is used for the alternators with the stator winding coil connected as per ‘delta’ scheme. The diode bridges with eight diodes are used with the stator winding coil connected as per “star” scheme.

To make the alternator operate more efficient and stable, the main diodes that are responsible for the current rectifying are connected with the additional three low-current diodes powering the voltage regulator and the excitation winding.

Diode bridge assembly

1, 2, 3 – diodes connected with a positive plate;

4, 5, 6 – diodes connected with a negative plate.

The features of the latest diode bridges

The value of the alternator output current rate depends on the engine crankshaft speed. The usage of the common diodes in the diode bridge may cause the voltage spikes up to 20V that does harm to the consumers. To make the output voltage the more stable the possible, the current diode bridges are equipped with the avalanche diodes instead of the common diodes.

Avalanche diode - it’s kind of Zener diode applied with the voltage won’t conduct the current until the voltage value gets higher than the rated value. This feature enables the voltage remain stable at the positive lead of the alternator terminal.

How to test and repair diode bridges?

Commonly, the visual inspection of the diode bridge cannot determine if it’s in order or not. Also, due to the usage of the powerful diodes designed for the high current rate, it’s not possible to accurate check the diode bridge condition using the multimeter.

For this reason, the car service stations use the special testers for the diode bridge diagnostics. MGS Equipment product range includes two testers that enable the revealing of the diode bridge malfunction - MS014 and MS021. The tester MS014 detects:

- breakdown of one or several diodes;

- fault of one or several diodes;

- mutual short circuit of heat sinks.

In addition to the mentioned malfunctions, the tester MS021 identifies:

- diode type (common or avalanche);

- diode degradation (enormous voltage drop to forward direction);

- the voltage of the reverse fault of the avalanche diode.

Visit the website to learn more about the equipment specifications or contact us +38 (067) 434 45 33(Viber, WhatsApp, Telegram)

COMMENTS