For many years, concerned individuals have been fighting to protect our planet's ecology. Their efforts have led to various outcomes, such as the ban on lead additives in fuel, the prohibition of asbestos in brake pad production, the introduction of emissions standards for internal combustion engines, and much more.

Diesel particulate filters (DPF) are a crucial component for the environmental safety of modern diesel engines. They capture and store solid particles (soot) from exhaust gases. However, using a vehicle with a DPF presents certain challenges related to the standard DPF cleaning system:

Incomplete Regeneration: If the regeneration process is not fully completed, such as during short city trips, the soot doesn't have time to burn off completely, leading to filter clogging.

Frequent Regeneration: Malfunctions in the regeneration system sensors, engine, or ECU can cause incorrect initialization of regeneration. This can lead to too frequent regeneration, resulting in increased fuel consumption, higher engine wear, and potential turbocharger failure.

What to Do if There Are Problems with the DPF?

In this case, the following steps are recommended:

1. System Diagnosis: First, determine the cause of the clogging. Without a thorough and complete vehicle diagnosis, any actions taken with the DPF are pointless. If the cause of rapid DPF clogging isn't addressed, a new filter will quickly become clogged again.

2. Fix Malfunctions Leading to Rapid DPF Clogging: Faulty pressure and temperature sensors, and a malfunctioning engine cooling system thermostat, can hinder the proper operation of the regeneration system. Check and replace all faulty elements if necessary. It is also recommended to change the engine oil out of schedule since diesel fuel can enter the engine's crankcase with a clogged DPF, degrading the oil's properties.

3. Clean the DPF: To do this, you will need to choose the most appropriate method:

1) Forced regeneration using special chemicals: Many service centers offer chemical cleaning of the DPF without removing the filter. In this method, a special chemical composition or several chemically active substances are sprayed into the filter through the pressure sensor hole. These substances dissolve the soot particles, helping them burn off during the regeneration process.

Cons:

Inability to assess the condition and integrity of the DPF's internal structure.

Not environmentally friendly. During the filter burn-off, all the chemicals used are released into the atmosphere.

- Unsafe for the engine. Forced regeneration takes about 40 minutes, during which the engine has to run at high RPMs while the vehicle is stationary. This operating mode, with insufficient cooling, is detrimental to the engine and could lead to complete failure.

2) Washing on a stand with preliminary soaking in a chemically active solution: A common method for removing soot from the filter. The DPF is removed from the vehicle, filled with a chemically active cleaning solution, and then washed with water using a special stand after a certain period. The chemically weakened soot is washed out of the filter by the water flow.

Cons:

Service station workers have to handle chemically active and hazardous substances.

Not environmentally friendly. All the used water requires special disposal methods. No filters can separate the chemicals from the water.

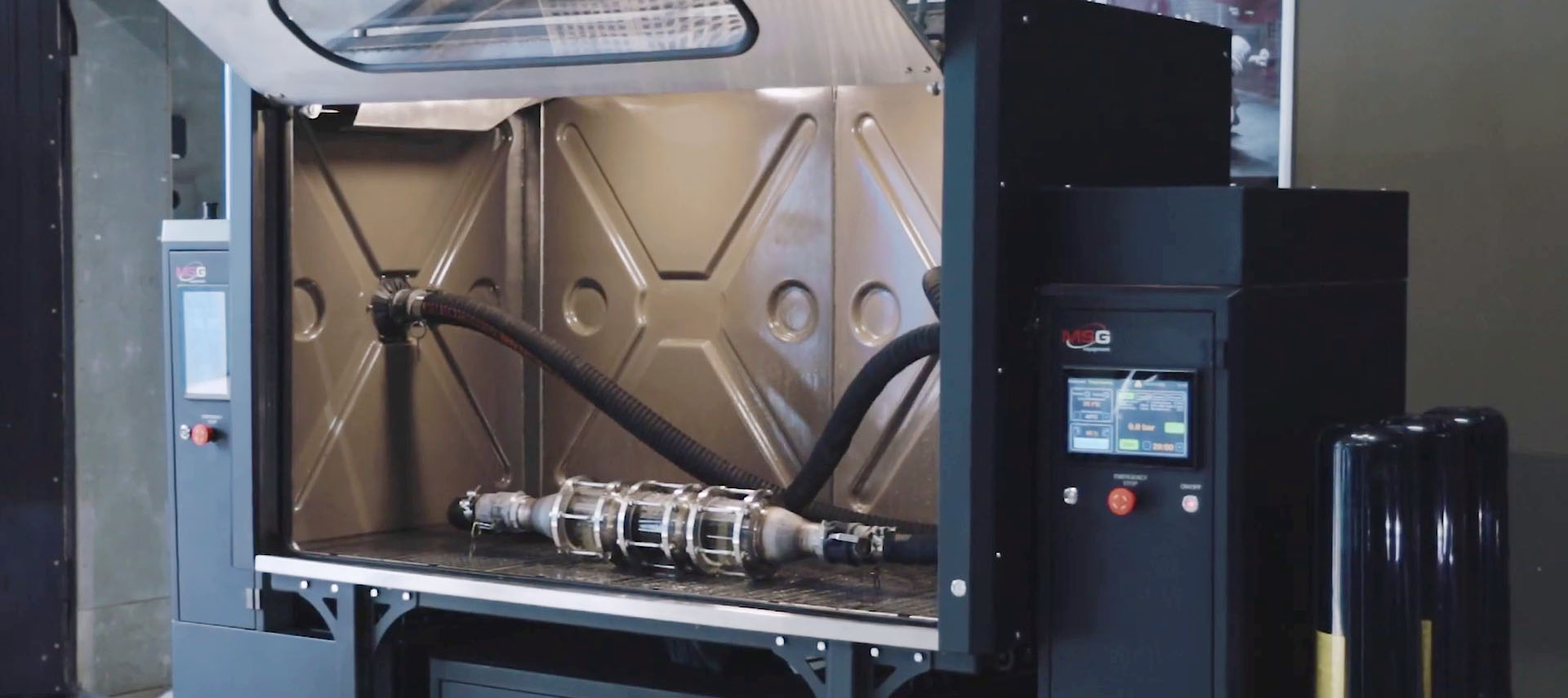

3) Closed-loop washing with fluid flow change using innovative dpf cleaning equipment: The most effective DPF cleaning method is implemented in the MS900 complex. The MS900 system cleans the DPF with a flow of warm water in a closed loop, periodically changing the flow direction. This flow change effectively separates soot and ash from the filter walls, and compressed air pulses enhance this effect. This approach allows thorough and quick DPF cleaning without using chemical detergents.

Cons:

- It is not possible to clean a particulate filter that has been contaminated with engine oil due to an engine malfunction. It is not possible to clean such a filter without the use of chemical cleaners.

4) Filter Replacement: In extreme cases, if the internal structure of the filter is damaged, a replacement with a new one is necessary.

Cons:

- High cost.

The DPF is an essential part of the emissions control system, and its proper functioning is critical for maintaining environmental standards and engine efficiency. It is also crucial to care for our planet by using timely equipment for DPF maintenance that:

Provides an effective cleaning method.

Has a low cleaning cost.

Is capable of cleaning DPFs for both passenger and commercial vehicles.

Requires minimal time for DPF cleaning.

Is easy to use.

Is environmentally safe..

COMMENTS