2000 – a start of a new millennium as well as a start of a new era of the development of car steering. This period is remarkable with the technological breakthrough from the hydraulic power steering (HPS) to electro-mechanical power steering (EPS). At present time, 98% of the manufactured light engine vehicles are equipped with EPS.

The advantages of EPS comparing to the traditional HPS are numerous. Here are some of most notable:

- the fuel consumption reduction: by 0.5 l per 100 km;

- the regular maintenance is not required;

- EPS enables many features work: assistance at the keeping of the traffic lane, automatic parking, lane change. EPS enabled also the development of the self-driving car.

Electric steering power became the essential part of modern car construction. In the nearest future EPS will be adapted to not only react to the speed changes but also to receive the information from either a navigation system, other cars or cloud servers.

EPS: weak points

Whatever EPS is perfect and reliable, any car owner may face its failure sooner or later. The experience and the statistics demonstrate that the lion’s share of EPS failures as well as of the failures of other steering racks result from the dust boot tearing with the following penetration of the water and dirt that generates the fatal corrosion and excessive wear. The second reason of the failures - the constructional features of a specific steering rack. For instance, the common reason of Mazda steering rack failure - torque sensor that gets out of order. Some steering racks have the electronic control unit in the bottom, and it’s often not protected. Therefore, any little stone that gets the control unit may break its cover. The water starts getting through, and electronic control unit gets out of order. One more common reason of the steering rack failures is the fair wear as well as a shock load at the driving bad roads.

Diagnostics of EPS failures

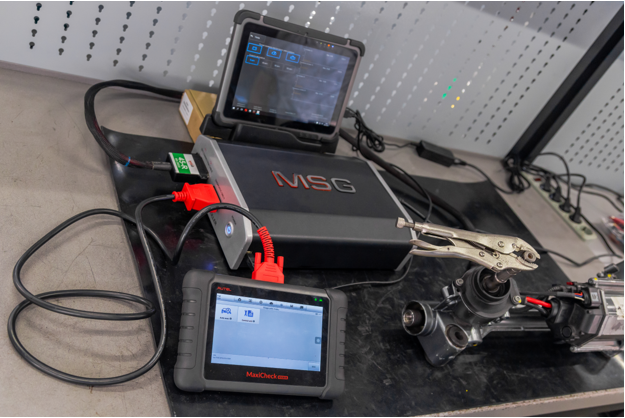

The dismantling of EPS unit commonly doesn’t help at the failure determining. EPS is a high-tech unit that requires the appropriate tool for the diagnostics. The MSG Equipment controller MS561 tests the units dismantled from a car: steering racks, EPS columns, EHPS pumps. The diagnostic scanner can be connected to the controller connector OBD II to read the errors from the control unit. Besides, it’s possible to delete the errors, either to code or update the software.

The controller MS561 is connected to the EPS unit with the special cables. At present time, the following cables are available:

- 45 cables for column diagnostics;

- 68 cables for steering rack diagnostics;

- 27 cables for pump diagnostics;

- 11 cables for the diagnostics of the steering racks of Japanese vehicles with MS550;

- 7 cables for the diagnostics of the digital torque sensors;

- 8 cables for the diagnostics of the steering racks controlled by FlexRаy protocol.

This cable set enables the diagnostics of more than 4000 car model units.

The key advantage of the controller MS561 is the capability to test the EPS units that are controlled by FlesRay protocol. These EPS unit types are installed to the German car makes: BMW, AUDI, MERCEDES-BENZ. To diagnose these rack types one should simulate the connection of the rack to the vehicle control unit and transfer the special codes to the steering rack at a certain time. To enable this feature, we’ve developed the special FlexRay cables that are equipped with the control unit that simulates the connection of the steering rack to the vehicle. It makes possible to diagnose and repair a FlexRay steering rack thoroughly.

Is it reasonable to repair EPS units?

The repair of the steering racks is cost-efficient for both car repair shops and their customers. Let’s check the case when the torque sensor of EPS of Mazda 6 (GH) 2010-2013 failed. The price of a new steering rack is around $1400 while its repair will cost around $400 - referring to the mentioned defects. The expenses difference is notable for a customer, while it’s also rather profitable for a car repair shop because the half of a repair price - repair service charge. It’s also profitable to repair the less expensive EPS units. For example, the replacement of the broken steering column flexible coupling of HYUNDAI Elantra 2010-2014 would cost around $100 while a new steering column costs $400. However, the situations are different, and it’s not always possible to repair a steering rack at the reasonable price, moreover, due to the lack of the spare parts the repair cannot be made at all.

To keep your stock full with the repair parts contact Master Service online shop. There you can buy the steering power components:

- steering rack adjustment nuts;

- flexible couplings;

- EPS steering rack protective covers;

- torque sensors;

- steering rack electric motors;

and other spare parts.

The components for the steering racks are of the following trademarks: MSG, Emmetec, ZF. They all conform with the international quality standards.

Summary

The controller MS561 is a perfect device for the diagnostics and repair of EPS units because it helps to not only reveal the failure reason but also to fulfill the complete set of works that guaranties the installation of a properly working unit to a car.

To take full advantages of the controller MS561, visit the training courses in the specialized training center of MSG Equipment. There the qualified specialists will teach you how to find the failure reason and eliminate it.

Besides, MSG Equipment offers the special tool for the EPS unit disassembling/assembling. It makes the disassembling process of some units easier and faster, and guaranties the top quality repair.

Our special tools range list:

• tool for the dismounting/mounting of a electric motor bearing nut

FORD, VOLVO

• tool for the dismounting a nut that connect the coupling with a shaft

MAZDA 6

• special tool for adjustment of steering column torque sensor

HYUNDAI ACCENT III

• tool for dismounting of rotor nut

LEXUS GS and IS II

• tool for the dismounting/mounting of bearing bushing

HONDA, ACURA, MAZDA,

• tool for the dismounting/mounting and adjusting of locknut

BMW, NISSAN, RENAULT, MERCEDES-BENZ, AUDI, SEAT, SKODA, VW, TOYOTA LAND CRUISER,

• tool for the dismounting/mounting of the pinion bottom nut

LEXUS, MINI, MITSUBISHI,

• tool for the dismounting of rotor position sensor

MAZDA

• tool for the dismounting/mounting of bearing lock nut

BMW

• tool for the engine dismounting

AUDI Q3, SEAT ALHAMBRA, VW PASSAT CC, VW PASSAT Variant, VW TIGUAN

• tool for the dismounting/mounting of ball screw bearing

MERCEDES-BENZ, LEXUS

• tool for the dismounting/mounting of bearing nut

FORD USA EXPLORER, LEXUS LS 460, BMW X5, BMW X6

COMMENTS